In light of the ongoing and increasing labor shortages in the construction sector, the call from Skills England for modern methods of construction (MMC) to “expand considerably” has never been more urgent. As noted in their recent report, sectors such as housebuilding, energy, and water infrastructure are heavily reliant on increasing the construction workforce to meet growing demands. Yet, despite the potential of MMC, or more precisely, industrialised construction (IC), to drive productivity and efficiency, its uptake remains insufficient to alleviate these labor pressures.

Why are MMC and IC underutilised in the broader market, and how can we boost uptake to unlock its potential?

The challenge facing the industry is twofold. First, the construction workforce is shrinking, and second, there is a critical lack of investment in the skills required to support new approaches that utilise industrialised methods of construction. But IC, when implemented correctly, can be a game changer. In sectors such as education, defence, and justice, where frameworks and standardisation of design are the norm, IC is already playing a transformative role. Projects in the Ministry of Defence (MoD) and Ministry of Justice (MoJ) have demonstrated how a structured approach to design and delivery can enhance uptake, boost productivity, and streamline the build process allowing us to do more with fewer, multi-skilled workers. However, the wider construction industry, particularly in private housing, has yet to fully embrace this.

So, why are MMC and IC underutilised in the broader market, and how can we boost uptake to unlock its potential?

The Need for Standardisation and Frameworks

As Skills England highlighted, the MMC adoption rate must increase significantly to address labor shortages. However, the uptake of industrialised methods using MMC is largely dependent on frameworks that ensure a consistent pipeline of projects. These frameworks, combined with a more standardised approach to design, are pivotal in realising the full benefits of IC.

At present, the private housing sector, which operates outside of typical frameworks, lacks the incentive and structure to adopt MMC at scale. Unlike single-client developments, such as those in the MoD and MoJ, private developers are driven by different market forces and often view MMC as a riskier and less profitable option. This hesitancy, coupled with a lack of standardisation, discourages investment in MMC technologies and industrialisation of constructionwhich are essential to overcoming the labor shortage challenge.

Aligning IC with Private Sector Needs

For IC to thrive, particularly in private housing, there needs to be a greater alignment of the demand profile to drive pipelines for investment and remove single point of failure risks. But the housing market does not like the idea of standardisation. Planning constraints demand contextual responses, and individual clients and developers want to differentiate themselves from each other. And so, the uptake of IC in the housing sector has been slow to take hold.

HLM Architects, Akerlof, Buro Happold and Limberger Associates’ open-access Digital Kit of Parts for low rise housing presents a solution to bridge this gap and drive IC in the housing sector.

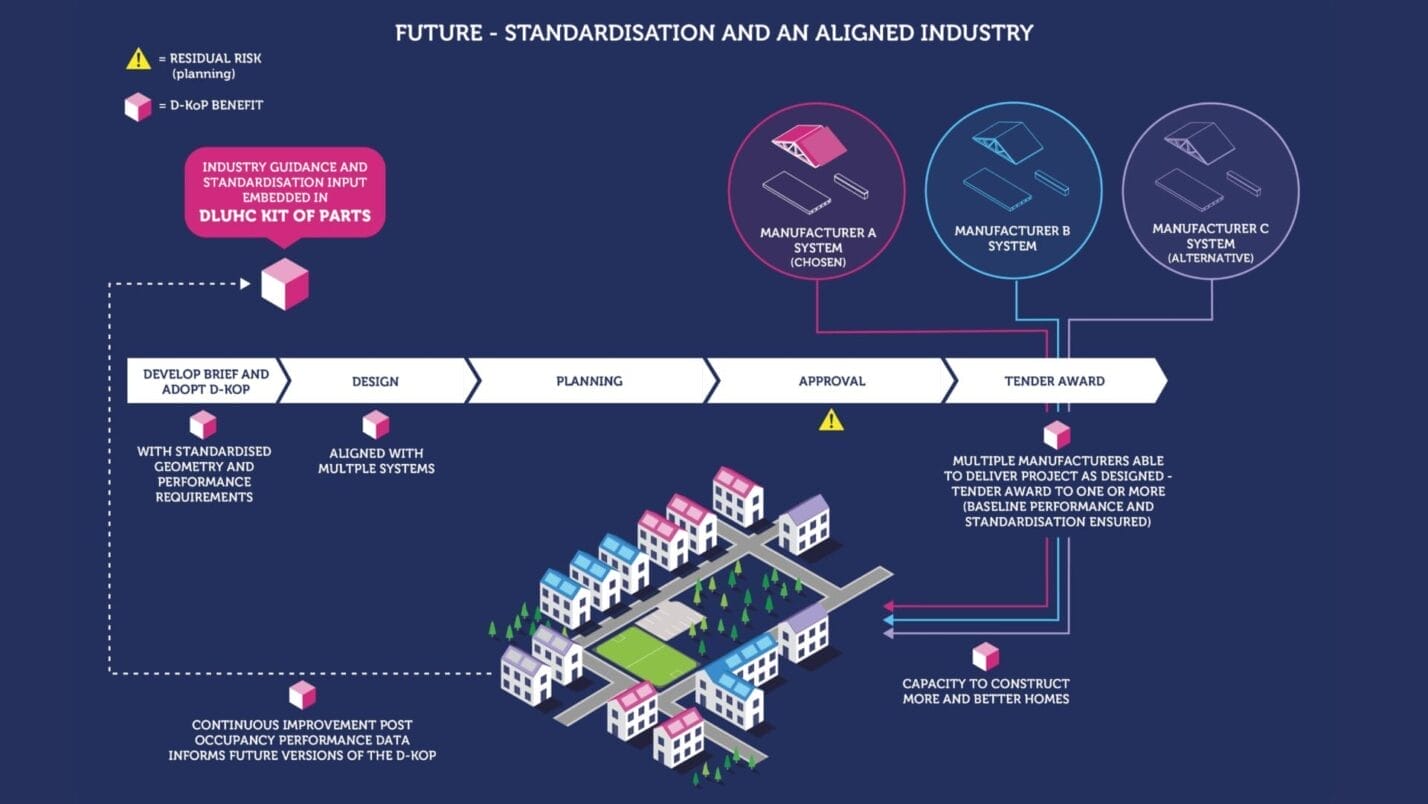

Commissioned by the Ministry of Housing, Communities, and Local Government (MHCLG), the Digital Kit of Parts (d-KoP) for low-rise housing links clients and designers to the key MMC supply chain information with a standardised digital language and format. This gives designers the information they need to design homes that can be delivered by multiple IC manufacturers. It also standardises performance around the MHCLG policy criteria, thereby guaranteeing a minimum level of quality. This re-aligns the process of designing for IC with traditional construction, making it much easier for developers to adopt because it more closely resembles their current working methods and risk models.

The interoperability of the design also means that the delivery is not optimised to a single manufacturer, but is able to be delivered by many different manufacturers who meet the performance specifications. This reduces the risk of single point of failure, thereby making it much more adoptable. These things together begin to knock down obsticles to adopting IC while at the same time consolidating the demand around a single performance specification and dimension range, making it easier for manufacuturers to standardise their products and processes. Reducing the complexity and resource-intensive nature of traditional builds reduces the need for highly specialised labour, helping to alleviate the shortage of skills. Furthermore, the digital kit provides a flexible, scalable solution that accommodates the diverse needs of housing providers, designers, manufacturers, and homeowners. This makes the digital kit of parts approach not only more efficient but also more adaptable to a wide range of housing designs, styles, and materials. Unlike the rigid models seen in other countries, such as the US, this approach leverages the diversity of the UK housing market, offering the best of both worlds, standardisation without sacrificing design flexibility.

The adoption of this standardised approach brings significant benefits to the housing sector

The Benefits for the Housing Sector and Beyond

The adoption of this standardised approach brings significant benefits to the housing sector. Firstly, it simplifies the design and construction process, reducing both time and costs. Secondly, it fosters greater collaboration across the supply chain by enhancing compatibility between products and systems, helping to bridge the gap between designers, manufacturers, and developers. Lastly, the digital nature of the kit ensures that it can continuously evolve, reflecting advancements in technology and industry practices, further enhancing its long-term value.

Although the d-KoP was initially targeted at low-rise housing, its potential extends far beyond that. The standardised framework could be applied across a range of sectors, offering a pan-departmental solution that enhances construction efficiency while supporting digital planning and building safety initiatives.

A Dynamic Framework for the Future

The Digital Kit of Parts is more than just a response to the current labor shortage; it’s a forward-thinking solution that has the potential to reshape the future of construction. By promoting standardisation while respecting the inherent diversity of the housing sector, this tool is designed to evolve with the industry, driving efficiency, innovation, and quality for years to come. Through this approach, we can reduce barriers to IC adoption, increase productivity, and address the skills shortage that continues to challenge the UK construction industry.

Investment, Skills, and the Future

To fully capitalise on IC’s potential, we must address the underlying issue of investment. Low profit margins in the housing sector have stifled the industry’s ability to invest in and adopt MMC and IC innovations. More needs to be done to create an environment where investment in industrialisation of construction is not only feasible but essential for staying competitive. This includes the expansion of government-backed frameworks and incentives that encourage developers to invest in the necessary skills and technologies.

I believe industry must embrace these changes to create a more resilient construction sector. By combining digital innovation, design standardisation, and a more strategic alignment with the private sector’s needs, IC can deliver the productivity gains the UK desperately needs. It’s time to move beyond seeing MMC and IC as a niche solution and instead position it at the heart of our strategy to solve the labor crisis, meet the country’s ambitious development goals and reshape the way we design buildings.