Industrialised construction, offsite construction, Modern Methods of Construction (MMC), Design for Manufacture and Assembly (DfMA) – the increasing significance of these terms throughout the industry demonstrates the rapid evolution of approaches to design and construction.

As ambassadors for the optimisation of MMC in project design and delivery, HLM’s approach is increasingly driven by DfMA.

There is understandably some confusion around these terms; here are some brief descriptions for clarity:

Offsite construction:

Offsite construction (also known as ‘offsite manufacturing’, ‘offsite production’ or ‘prefabrication’) refers to components and/or assemblies which are manufactured offsite, before being installed.

Modern Methods of Construction (MMC):

The term used to capture processes and building methods designed to improve time and productivity onsite, as categorized in the UK Government’s MMC Definition Framework.

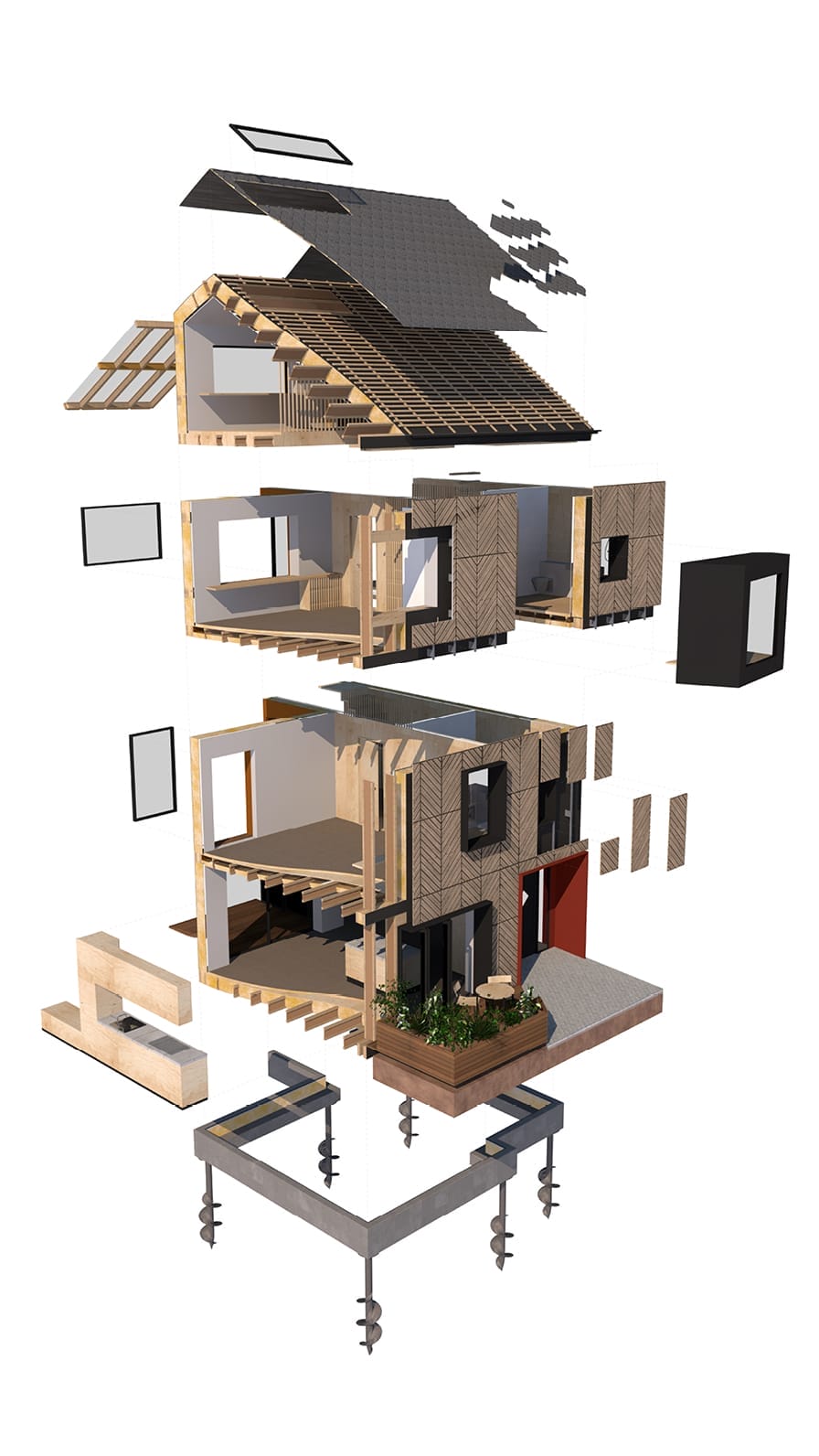

Design for Manufacture and Assembly (DfMA):

DfMA is focused on rationalizing the design process of buildings, to facilitate offsite manufacture and assembly.

We firmly believe that the opportunities for DfMA in improving MMC uptake are yet to be fully realized, and that new ways of working and better collaboration are needed to support this.

As ambassadors for the optimization of MMC in project design and delivery, HLM’s approach is increasingly driven by DfMA. By designing with offsite manufacture, platform design and countless other ‘modern’ methods in mind, project certainties – cost, programme length, quality, and sustainability – are increased, providing clear benefits to all stakeholders.

Unusually for architects, we entirely embrace the concept and benefits of MMC, wholly acknowledging the improvements that innovation brings. We have long endorsed the importance of early engagement with the entire supply chain to ensure the success of MMC in construction, and our work with key collaborators has proved the possibilities of this, for example:

- Dinton Activity Centre – Wokingham Borough Council’s first net zero carbon in operation building; 85% offsite construction;

- HMP Five Wells – saved 54,000 onsite hours of construction through offsite manufacture.;

- Single Living Accommodation for the MoD – 33% reduction in programme delivery; u-values aligned to Passivhaus standards;

- Product-Based Building Solution (PBBS) Demonstrator with Laing O’Rourke – Average of 43% reduction across delivery, lead time, labour and assembly time.

An industry-wide collaboration on pursuing these innovations will enable the entire supply chain to access comprehensive information, supporting wider goals and higher-quality outputs.

As designers who have been pioneering an MMC approach to construction for over twenty years, we have seen first-hand the challenges that changing technology and methods bring to the industry. However, we firmly believe that the opportunities for DfMA in improving MMC uptake are yet to be fully realized, and that new ways of working and better collaboration are needed to support this. The ‘PBBS Demonstrator’ project with Laing O’Rourke, and our involvement in the Department for Levelling Up, Housing and Communities’ ‘MMC Standardisation and Kit of Parts’, are examples of how our architectural expertise is elevating MMC. We must equip all contributors with confidence in innovations in design (DfMA), components (offsite) and methodologies (MMC), dispel the myths and share best practice across the industry.

The sustainability goals of construction are only going to become more stringent. An industry-wide collaboration on pursuing these innovations will enable the entire supply chain to access comprehensive information, supporting wider goals and higher-quality outputs. We’re innovating alongside partners in this area, creating accessible tools and platforms for architects, contractors and suppliers, and enabling informed decision-making – all of which will aid industry adoption.

If you’re interested in finding out more about our DfMA projects, visit our DfMA page, or download our new and updated brochure below.